You’re in the final rounds of decision making for your business’ inventory software, you see the value, internal stakeholders see the value, you pull the trigger. There’s excitement about what the future holds, how the solution will save time and money, even your finance department is smiling and they don’t usually do that. Now comes the hard part, implementing it without bringing your company to a halt.

- How will you integrate this software into your daily operations?

- Do we start using it in one department or all of them?

- Who is going to train our employees?

Skipping inventory software onboarding may seem like a cost-saving measure, but in reality it often leads to inefficiencies in your inventory management. These inefficiencies can lead to lost revenue and increased expenses, such as increased labor costs and lost sales due to stockouts. When employees are not properly trained on the software, they may not be using it to its fullest potential or make properly trained decisions. As the expression goes, a dull blade is more dangerous than a sharp one.

Here’s 3 Vital Benefits that Inventory Training can provide your business

DATA SETUP

Your business can never reach maximum success with poor data, you will always lack essential information to make your key business decisions. For an inventory based business, this data starts with accurate inventory data. Without proper onboarding, the software may not be configured correctly, resulting in inaccurate inventory counts, stock levels, and organization, which will have a significant impact on the company’s bottom line.

For example, if the software is not configured correctly, workers will not properly track items or materials, processes will be confused, and end results can be stockouts or unaccounted orders, which can result in lost sales and a decrease in customer satisfaction. Customers may become frustrated if they are unable to purchase the products they need, and may take their business elsewhere. Additionally, inaccurate inventory data can also lead to overstocking, which can result in additional storage costs and potential waste.

Lack of accurate inventory data impacts your company’s ability to make informed business decisions, identifying trends and patterns in the inventory, which affects the ability to predict demand, forecast future sales and make decisions on purchasing, stocking and pricing.

Want to know what’s worse than not meeting supply demands? Not meeting mandatory regulations. For example, industries like healthcare, food and beverage, or retail, accurate inventory data is essential for compliance with regulations related to product traceability, expiration dates and safety. Inventory Software Provides essential tools for recording and maintaining necessary information that you need for these regulations, but if the software is not properly set up or maintained you’re going to have a fines and penalties headache down the road.

SCALABILITY

Did you want to grow your business? Then your current process needs the ability to scale up without losing what made it successful in the first place. When a company decides to skip the inventory software onboarding process, they may not fully understand the capabilities of the software or how to properly configure it. It doesn’t mean the solution won’t work, but it’s not operating at full effectiveness, and as your company grows, that underperforming process will become an unintentional standard.

For example, if the software is not configured correctly, your company may handle regular order levels just fine, until the “big one” comes in. You landed the big client, or blew up on social media, etc, but now you face a deluge of orders and your process cannot keep pace. Similarly, if the software is not set up to handle multiple locations, it may not be able to accurately track inventory across different warehouses or retail stores. Without the ability to scale the software to meet your company’s boom times, you may be forced to finally invest in proper training, but the result is additional costs of downtime, lost revenue, and customer impression.

Another vital aspect of scalability is the ability to integrate with other systems. Many inventory management software have the capability to integrate with other business systems such as accounting software, e-commerce platforms, and shipping and logistics systems. Without proper onboarding, your company may not understand how to take advantage of these integrations, resulting in manual data entry and likely human error.

Without the ability to scale, your company becomes limited in its resources to expand into new markets or introduce new product lines. Without a system that can handle the increased complexity and volume, you may struggle to keep up with demand and miss out on big growth opportunities.

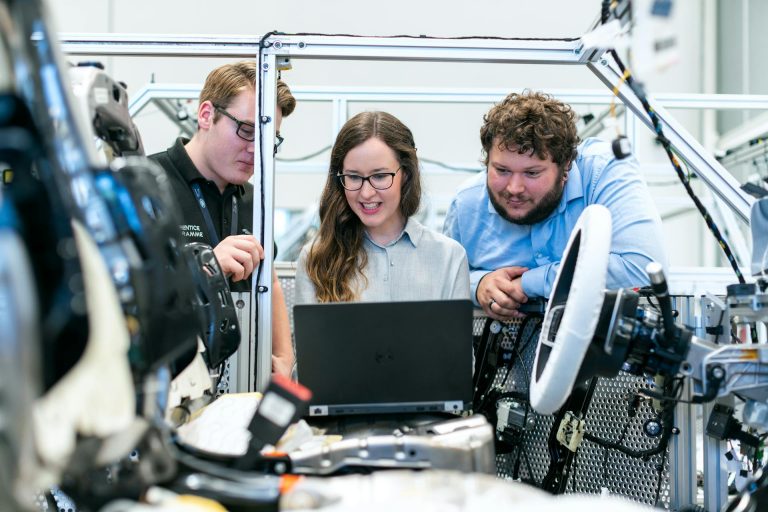

EMPLOYEE TRAINING

One of the most substantial hidden costs of forgoing inventory software onboarding is a lack of employee productivity. Without the proper training, your employees will not know how to use the software effectively; this includes lost time, lost items, and more errors, all of which can have a significant impact on the company’s bottom line.

If employees don’t understand how to use the software, or how it can speed up their own day, they will rely on what they did before. They don’t understand the value because they don’t understand the software. There may even be frustration with the software, leading to a high turnover rate and the need to constantly train new employees. This can create an additional burden on the company, as it will need to spend time and resources training new employees.

This lack of employee productivity impacts the company’s ability to grow and expand. If employees are struggling to use the software effectively, it can make it more difficult for the company to keep up with demand and may miss out on potential growth opportunities. Employee onboarding is vital in your business’ inventory management.

BACK TO SCHOOL

When planning for your inventory software purchase, remember the solution itself is a tool, but it is how you implement that tool across your entire company which dictates the success of that software. The more your departments and employees understand the process, workflows, and even data points that are made possible because of the inventory management solution, the more opportunities you have to grow.